Essential Tools for Basic Home Maintenance

Respect these time-saving devices by following essential precautions. Always disconnect power before changing bits or blades. Secure workpieces firmly to prevent dangerous movement during operation. Maintain clean, dry work areas to avoid slips or electrical hazards. Store tools with safety locks engaged and sharp components covered. Regular inspection of cords and switches prevents unexpected malfunctions.

Drill Drivers: Versatility in Your Hands

This workhorse tool combines rotational and hammering actions for diverse applications. Variable speed triggers allow precise control for different materials. Invest in quality drill bits matched to specific materials - masonry, metal, and wood each require different designs. Clutch settings prevent over-driving screws, while auxiliary handles provide stability for heavy-duty drilling. Keep batteries charged and store in temperature-controlled environments.

Saws: Precision Cutting for Any Project

Circular saws make straight cuts through various materials when guided properly. Reciprocating saws handle demolition work and tricky angles. Blade selection directly affects cut quality and safety - match tooth count and design to the material. Always use appropriate safety guards and maintain firm two-handed control. Allow the blade to reach full speed before contacting material for cleaner cuts.

Sanders: Smoothing Surfaces for Perfection

Power sanding transforms rough surfaces efficiently. Random orbital sanders minimize swirl marks while detail sanders reach tight corners. Progress through grits systematically - starting too fine wastes time, while skipping steps leaves scratches. Use dust collection systems to maintain visibility and respiratory health. Light, even pressure prevents uneven surfaces and premature wear on sanding pads.

Impact Wrenches: Effortless Fastening

These specialized tools deliver high torque with minimal user effort. Impact mechanisms protect wrists from reactive forces during heavy-duty fastening. Socket retention systems prevent dangerous projectile situations. Use only impact-rated sockets to avoid shattering under sudden torque loads. Regular lubrication of the hammer mechanism maintains performance.

Multi-Tool Powerhouses: Versatility in One

Oscillating tools handle cutting, sanding, and scraping with quick-change accessories. Their compact size reaches areas larger tools can't access. Variable speed controls adapt to different materials and tasks. Support the tool near the work surface to minimize vibration and improve control. Keep spare blades handy as they wear quickly during intense use.

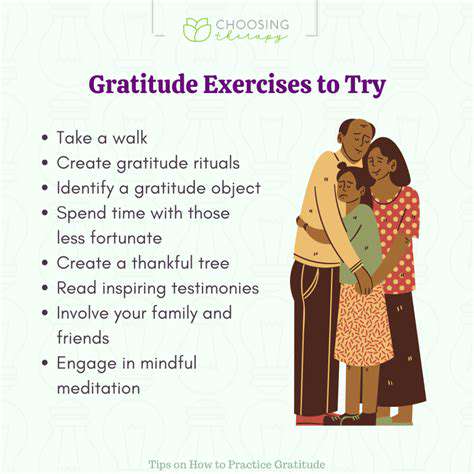

Mindfulness practices alleviate anxiety and enhance emotional management skills

Measuring and Marking Tools

Measuring Tapes

These flexible rulers adapt to curved surfaces and long distances. High-contrast markings improve readability in various lighting conditions. Sturdy cases withstand job site abuse while smooth retraction mechanisms prevent frustrating tangles. For precise inside measurements, remember to account for the tape's case dimension. Regular cleaning prevents dirt buildup that can obscure markings.

Rulers

Metal rulers offer durability for shop environments while transparent plastic models allow visibility of underlying work. Non-slip backings prevent dangerous movement during marking. Combination squares incorporate level bubbles and scribing tools for multifunction use. Store rulers flat to prevent warping that compromises accuracy. Etched markings outlast printed graduations under heavy use.

Levels

Digital levels provide precise angle measurements to tenths of degrees. Magnetic edges conveniently adhere to metal framing during installation. Torpedo levels fit in tight spaces while longer models ensure straight runs over distance. Calibrate levels periodically by checking against known flat surfaces. Protective end caps prevent damage to vials during storage.

Squares

Combination squares adjust for various marking needs with integrated rulers. Cast iron squares maintain accuracy despite job site abuse. Speed squares quickly mark common angles for roofing and framing. Verify squareness periodically by marking a line, flipping the tool, and checking alignment. Store in protective cases to prevent edge damage.

Compasses

Quality compasses maintain consistent radius settings during use. Locking mechanisms prevent accidental adjustments while drawing. Replaceable leads accommodate different line widths. For large circles, beam compasses provide stability and precision. Keep pivot points lubricated for smooth operation.

Marking Pens and Pencils

Fine-tip markers create precise layout lines on various materials. Chalk lines snap straight guidelines over long distances. Silver pencils mark clearly on dark materials. Keep markers capped when not in use to prevent drying. Store pencils sharpened for immediate use when needed.

Marking Gauges

Wheel-type gauges produce cleaner lines than traditional pin styles. Micro-adjustment capabilities enable precise spacing setups. Some models incorporate measurement scales for direct reading. Apply consistent pressure when scoring to maintain depth uniformity. Store with cutting wheels protected to maintain sharpness.

Safety Gear and Organization

Proper Helmet Usage

Head protection requires proper fit and maintenance. Adjustable suspension systems customize comfort while ensuring protection. Replace helmets after any significant impact, even without visible damage. Ventilation channels improve comfort during extended wear. Bright colors enhance visibility in low-light conditions.

Organized Storage for Tools and Equipment

Shadow boards visually indicate missing tools. Pegboard systems adapt to changing tool collections. Labeled bins sort small parts efficiently. Mobile carts bring tools directly to work areas. Regular inventory checks prevent project delays from missing items.

Essential Safety Apparel for Protection

Cut-resistant gloves specify protection levels for different hazards. Safety glasses with side shields provide comprehensive eye protection. Steel-toe boots should meet current industry standards. Hi-vis clothing maintains visibility in busy work areas. Layer clothing appropriately for temperature regulation.

First Aid Kit and Emergency Procedures

Customize kits for specific work environments. Regularly check expiration dates on medical supplies. Eye wash stations require periodic flow testing. Post emergency numbers conspicuously throughout work areas. Conduct regular drills to maintain preparedness.

![Guide to Learning [Specific Art Form]](/static/images/31/2025-05/FromSimpletoComplex3AStep-by-StepPaintingExercises.jpg)